AK-I Tufting Machine Adjustments

On this page you will find an overview of the different micro-adjustments you can perform on your AK-I tufting machine. If you are experiencing any issues with your machine, we recommend that you click the troubleshooting link below which provides helpful advice to get you back up and tufting.

Disclaimer

Tuftbox is unable to accept liability for any damages that occur whilst following these tutorials. Tufting machines should be repaired by qualified individuals using identical replacement parts, this will ensure that the safety of the machine is maintained. If you purchased your tufting gun from us, you can reach out for troubleshooting support, repairs and replacements via emailing help@tuftbox.co.uk.

Please make sure that you turn off and unplug your machine before performing any adjustments.

Every time the white square bearing on the lower metal rods moves into the back position it must come in contact with the break bar. The bar should be perpendicular (90°) to your machine, like in the below pictures. To fix a misaligned bar, loosen the break bar bolt with the smallest allen key supplied with your AK-I. Gently rotate the break bar so it is perpendicular to the machine and tighten the bolt.

Adjusting the AK-I Foot Position

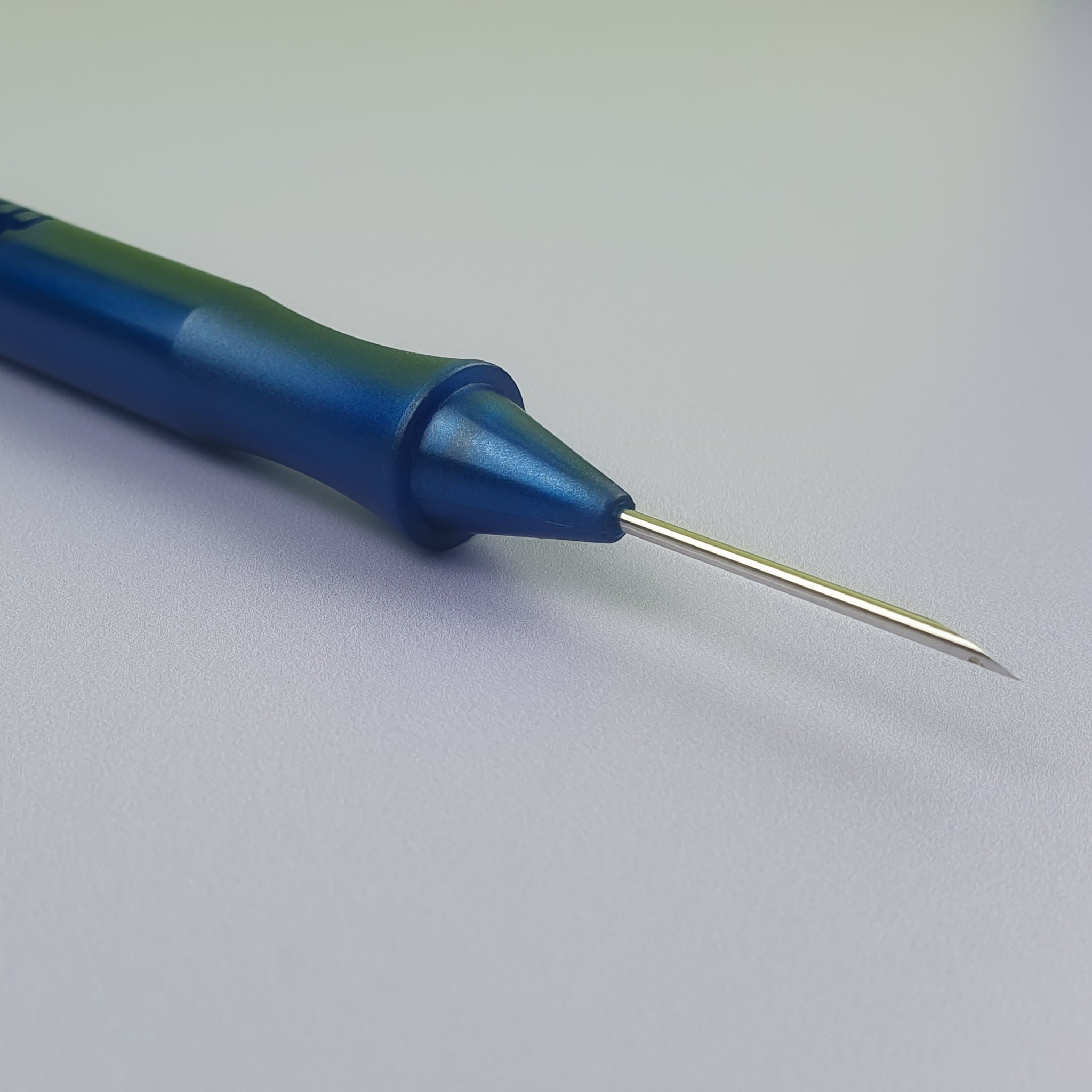

The foot and the needle of the AK-I work together and need to be correctly aligned for smooth operation of the machine. To check the foot position first ensure that your machine is turned off and unplugged. Rotate the white gear manually by hand until the needle is sticking out at its furthest point forward. At this position the two prongs of the foot should be aligned with the bottom of the eye of the needle (see image labelled “Needle Eye Alignment” below). When looking at the machine from the front, the needle should also be positioned in the very centre of the foot (see image labelled “Perfectly Centred Needle”).

To adjust the foot/needle relationship, use the largest allen key supplied with your AK-I to loosen the foot height adjustment bolt. This is located on the underside of the foot and can be seen in the picture below. You can adjust the foot by sliding it back and forth along the channel until it is lined up with the back edge of the needle eye. Make sure that the needle is centred inside the foot and tighten the foot height adjustment bolt.

Adjusting the AK-I Scissor Closer

The scissors of the AK-I work via a mechanical process, a metal block at the front of the machine closes the scissors. This block should close the scissors when they reach their maximum extension. To examine where your scissors are closing, make sure your machine is turned off and unplugged. Rotate the white gear manually until it completes a 360° rotation. You should see the scissors come out of the end of the needle, perform the cut action and then retreat back into the machine. If the scissors are not closing (performing the cut action) or if the scissors are closing too early then you will need to perform a micro-adjustment to the scissor closing block.

Using the middle-sized allen key provided with your AK-I, gently loosen the scissor closer bolt. You can now adjust the scissor closer by sliding the piece to the left or right within the channel. Move the piece in small increments until you find the position where the scissors are closing at their maximum extension - you want the scissors to cut when they are sticking out the furthest from the machine. When closed at the maximum extension the scissors should have a slight v shape at the end of the blade. They should not be over-closing (overlapping) or under-closing (with a gap between the blades). Once adjusted, tighten the scissor closer bolt to lock in place.

Sometimes the vibrations from normal use over time or an incorrect pile height adjustment can cause the bolt on the white gear to become loose. A loose bolt can result in instability of the lower machine bar, as the gear rotates the bar can jerk back and forth in the channel where it attaches to the gear.

The bolt should be securely attached to the centre-most point of the gear (see images below). Using a small adjustable wrench or an 8mm spanner, the bolt can be tightened by turning clockwise using light pressure on the wrench, be careful when tightening as over-torquing can result in stripping or breakage.

The cloth pusher looks like a black metal tongue, it is positioned underneath the foot and extends forward with the scissors. When the scissors are in their furthest position forward and closed (performing the cut action) there should be a 6-7mm gap between the cloth pusher and the foot of the machine (see image below).

To adjust the position of the cloth pusher, loosen the lower bearing screw gently using the smallest allen key, only turn anti-clockwise once or twice until you are able to manually move the cloth pusher. Once you have repositioned the cloth pusher, remember to tighten the lower bearing screw.

Adjusting the AK-I Scissor Opener

The scissors of the AK-I should open when the needle is in the furthest position forward and the scissors are in the furthest back position. To examine where your scissors are opening, make sure your machine is turned off and unplugged. Rotate the white gear by hand until it completes a 360° rotation. Watch the needle and the needle channel underneath your machine, you should see the scissors open when the needle is in its maximum forward extension (sticking out the furthest from the machine). If the scissors are not opening, or if they are opening too early or late, you will need to perform a micro-adjustment to the scissor opener.

The scissors of the AK-I work via a mechanical process, a metal strip (the scissor opener) forces the scissors open. The upper metal rod on the left hand side of your machine houses the scissor opener. The opener block attaches to a thin strip of metal that rests in the channel (see images below).

Loosen the scissor opener screw counterclockwise using the smallest allen key that comes with your AK-I. Gently pull the block backwards on the rod. Manually rotate the gear until the scissors are in the furthest position backwards and the needle is at its maximum distance forwards. Check that the scissor opener is still in the channel as it can pop out when the screw is loose.

Whilst watching the scissors, gradually move the opener block towards the needle (the front of the machine). You will feel resistance as the scissors start to open. Continue moving the block forward until the scissors are fully open. The scissors are fully open when they have met the full width of the channel. Once the scissors are opening at the correct point, tighten the scissor opener screw.

Adjusting the AK-I Needle Position

When the scissors are fully forward the tip of the needle should not extend beyond the two prongs of the foot. The image below shows the correct alignment of the needle when the scissors are at their maximum extension.

If you find that the needle is sticking out past the foot when the scissors are forward you will need to adjust the needle position. You will need a Phillips PH2 screwdriver to remove the plastic casing that surrounds and protects the gear. Fully unscrew the middle screw on the left hand side of your machine (see image below) and place the screw in a safe space for later. Unclip the plastic casing at the top of the machine to remove the left half.

Make sure the scissors are still positioned forward. Loosen the upper rod nut using a small adjustable wrench or an 8mm spanner (see images below). The bolt can now slide back and forth along the channel that connects it to the top of the machine. Move until the needle is in line with, or behind, the prongs of the feet. Retighten the upper rod nut. Reconnect the plastic casing and clip the top back together and replace the screw that secures the casing.

After moving the needle backwards you will likely need to adjust other parts of the machine including the cloth pusher, the scissor closing and the scissor opening mechanisms. You can find instructions for adjusting these parts within this guide.

Adjusting the AK-I Trigger Screw

When excessive force is applied to the machine’s trigger button it can become stuck in an engaged position. To fix a sticky trigger you will need a Phillips PH2 screwdriver. Ensure that your machine is switched off and unplugged. Locate the trigger screw in the machine’s handle (see image below). Turn the screw a small amount (180° degrees), this should release the pressure and enable the trigger to function effectively again.

Adjusting the AK-I to Factory Settings

Even a small misalignment of parts within your AK-I can disrupt the mechanics of the machine. Misalignment most often happens when a pile-height adjustment is made incorrectly. The best way to realign your machine is to restore it back to factory settings.

To restore your machine you will need: the 3 allen keys that came with your AK-I, a small adjustable wrench (or an 8mm spanner), a PH2 Phillips screwdriver and callipers (or a ruler). Make sure that you turn off and unplug your machine before performing any adjustments.

The first step is to measure the black upper and lower bearing rods. Using your callipers or ruler, measure the distance between the two bearing rod nuts (see the below images). The factory settings of the upper bearing rod are 53mm and the lower rod 44mm - this is the highest pile height setting for the machine. The lower rod should always remain at 44mm and should not be adjusted.

You only need to loosen the front nuts nearest to the needle to change the length of the bearing rods (see images below). Unscrew the rod nut using your adjustable wrench (or 8mm spanner) and keep it in a safe place. Loosen the bearing rod nut. You can now lift and detach the rod. Twist the end of the rod (the rod end bearing) to change the length of the rod. Clockwise will increase the length, counter-clockwise will decrease the length of the rod. Remeasure the length of the black rod and make further adjustments if needed. Reattach the rod and secure the rod nut back in place using your wrench/spanner (clockwise to tighten). Tighten the bearing rod nut.

Once the upper and lower bearing rods are back at factory setting, follow the instructions within this page for the below adjustments:

1. Scissor Closing

2. Scissor Opening

3. Foot Positioning

4. Cloth Pusher

5. Needle Position

Once you have completed the above adjustments, manually rotate the gear a few times again and triple check that you have a smooth operation and everything is aligned. Triple check that you have tightened all of the bolts. Lastly, perform the routine maintenance work on your machine e.g. cleaning and oiling (as outlined in your AK-I manual). After this you are ready to plug back in and start tufting at the original factory settings!

Adjusting the AK-I Pile Height

To change the pile height on your AK-I you will need; the three allen keys that came with your AK-I, a small adjustable wrench (or an 8mm spanner), a PH2 Phillips screwdriver and callipers (or a ruler). Make sure that you turn off and unplug your machine before performing any adjustments.

The pile height can be set through adjustments to the upper bearing rod. Shortening the upper bearing rod means a longer pile, extending the length of the upper bearing rod means your machine will tuft a shorter pile.

Highest Pile = Upper Bearing Rod measures 53mm

Lowest Pile = Upper Bearing Rod measures 60mm

The lower rod should always remain at the factory settings of ~44mm and should not be adjusted. To check the length of your upper bearing rod use callipers or a ruler to measure the distance of the black rod between the two bearing rod nuts (see the below images).

To change the length of the upper rod you only need to loosen the front nuts nearest to the needle (see images below). Unscrew the rod nut using your adjustable wrench (or 8mm spanner) and keep it in a safe place. Loosen the bearing rod nut. You can now lift and detach the rod. Twist the end of the rod (the rod end bearing) to change the length of the rod. Clockwise will increase the length, counter-clockwise will decrease the length of the rod. Remeasure the length of the black rod and make further adjustments if needed. Reattach the rod and secure the rod nut back in place using your wrench/spanner (clockwise to tighten). Tighten the bearing rod nut.

Now that you have made adjustments to the upper bearing rod you will need to check and recalibrate the positions of other parts of your machine. Follow the instructions within this page for:

1. Foot Position

2. Cloth Pusher

3. Scissor Closing

Once you have completed the above adjustments, manually rotate the white gear a few times again to test that your machine rotates smoothly and everything is aligned. Triple check that nothing is loose. Lastly, perform the routine maintenance work on your machine e.g. cleaning and oiling (as outlined in your AK-I manual). After this you are ready to plug back in and tuft at your new pile height setting!